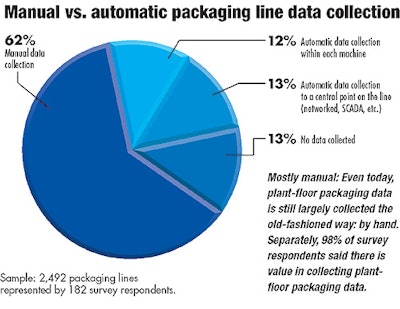

Here we are in the future—the year 2003—and our latest survey reveals that most packaging lines are still firmly rooted in the past. Of the more than 2ꯠ packaging lines studied for this survey, most are still not networked and rely on manual data-collection methods. The charts on these pages give the complete picture.

However, those who have figured out how to collect, share, and convert data into usable information say the payoff is worth it. The quotes that begin on this page tell their story.

What they said

We asked survey respondents to identify improvements or changes made based on packaging line data that had been collected and analyzed. Here’s what they said:

Streamlining materials

TOBACCO

“[We have] better accountability of materials (labels, foil, etc.) by comparing production numbers to vendor counts and weights. Serves as an indicator in quality issues [that could require] corrective actions.”

WINE

“[We have made] bottle design changes in fill point, bottle contact points with regard to breakage issues, [and changed] label size and placement to improve mass conveyance while minimizing label damage.”

DRIED FRUIT

“Decreased our bag loss by converting to a stiffer material when losses indicated that the material currently in use was too high. Reduced the cost of our zipper by not using the higher end zipper, when the lower end tested out fine.”

Boosting efficiency

PHARMACEUTICALS

“Downtime was collected, organized, and summarized from highest to lowest contributors. Top ten causes of downtime were addressed. Line output has risen by approximately 10% since the last study was completed.”

CONTRACT PACKAGER

“We actually make hourly adjustments to labor, automation, and materials as we view reports and a constant ticker that runs on all company computers. These can be mechanical, such as different machinery, adding guiderails, etc. Or they can be personnel-related, e.g., an experienced operator taking the place of a new one to overcome deficient production output.”

FOOD

“Increased OEE (Overall Equipment Effectiveness) by an average of 12% across all lines.”

FOOD

“We sat down with our supplier and cooperatively looked at and analyzed operations of our problem lines in order to ensure they were properly set up and the inbound packaging was in spec. That process lowered the waste percentage on those lines dramatically.”

FOOD

“We have made enough improvements in the areas of productivity, weight control, and waste reduction to show the value of data collection. Now we have approval to install the equipment necessary to automatically collect data and summarize it into useful forms.”

CHEMICALS

“We publish data and trends to allow other departments to assist production in improvements to packaging lines.”

Equipment upgrades

OFFICE PRODUCTS

“We search for the highest incident and failure areas and focus upgrades and improvements there. Recent work included rework of a cartoner infeed for high-speed insertion, orientation of product in a loading station, and carton forming.”

PET CARE

“We are using data to justify the purchase of new equipment. We have purchased three automated lines in the last two years to improve efficiency and productivity.”

Quality assurance

TOBACCO

“[Benefits include] increased product quality, lowered line downtime, increased equipment reliability, increased just-in-time capability, and decreased product waste.”

BEVERAGE

“Glass bottle breakage was substantially reduced by changing conveyor speed and especially making sure of smooth transition from one conveyor to the other.”

Maintenance

BEER

“We schedule equipment overhauls and replacement based on the downtime data collected over time. We also use it to prioritize routine maintenance and pinpoint vendor-related raw-material defects.”

See sidebar to this article: Why this survey is different

See sidebar to this article: Methodology