In general, the adaptation of digital protocols like EtherNet/IP or Profinet has made it easier to use and access multivariable measurements, according to Ola Wesstrom, senior industry manager of food and beverage for Endress+Hauser. With these protocols, just one set of wires provides measurement information along with very advanced diagnostic capabilities.

It also provides the added possibility of doing verification on instruments, he adds. “It brings up the overall trust of measurements,” he says, pointing to the very real possibility that instruments could start to drift a couple weeks after annual calibration. Onboard verification of instruments provides reassurance that the measurement is correct. “Very fast implementation of EtherNet/IP in the food industry has really opened up this possibility.”

>>Read more about the latest sensor innovations in the food and beverage industry in "New Technologies Feed the Hunger for Information."

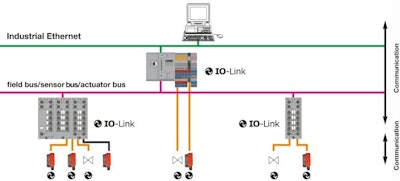

Several sensor suppliers pointed in particular to the increasing prevalence of the communication protocol IO-Link and what that has meant for industry, providing instant information on product status as well as the health of the sensor. “Data can include runtime data, temperature information, and time series output data, which can all be used to improve productivity by showing trends in machine failure as it relates to reduced sensor functionality, damage, or failure,” says Michael B. Hamoy, product manager for sensors at Omron Automation America.

Through the IO-Link Consortium, suppliers have come together to agree on providing the same information. So, in theory, any vendor’s IO-Link sensor can go onto any IO-Link system. From a technology perspective, IO-Link provides simplified installation, automated parameter settings, and expanded diagnostics.