Founded in 1998, Ithaca Beer Co. Ithaca Beer Co. now brews about 25,000 barrels of beer annually and distributes it to 15 states. To ensure continued quality, consistency, and profitability of its craft brews as the company scales up, the Ithaca, NY, brewery automated part of its brewing process by installing a standardized yet customizable control platform to gain visibility into its operations and drive efficiency while still having the flexibility to fully automate its production in the future.

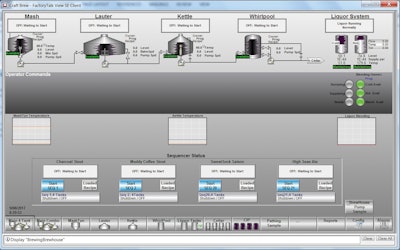

The system integrator that implemented the new Factory Talk Craft Brew solution from Rockwell Automation is OBG, a member of the Rockwell Automation Partner Network program. The pre-configured system offers cost-effective, flexible control to easily customize and automate a craft brewhouse. The platform is pre-engineered, -programmed, -tested, and -validated, significantly reducing commissioning and startup time.

“It was important for us to look for a solution that was easy to customize,” says Andrew Hausman, Head of Brewing Operations at Ithaca. “We do not have a fully automated brewing process, so modifications were necessary. Plus, the solution is scalable for future growth and production changes, which was also an important part of our selection process.”

With the FactoryTalk Craft Brew system, Ithaca Beer Co. is able to leverage most of its current assets and installed base, including existing I/O, variable-speed drives, and controllers — another key reason the company decided to standardize on the Rockwell platform.

Integrated and automated batch reporting offers electronic batch information directly through the HMI. In the past, the brewers had to manually write a batch report for every brew, which included entering important recipe information like gravities and pH levels manually. The new solution offers visualization and the capability to store and trend key batch data. It also simplifies troubleshooting efforts and allows brewers to better compare a “golden batch” to a batch with quality problems, saving hours of recipe adjustment time.